Our Services

- Home

- /

- Services

Hot Dip Galvanizing is the process of coating iron or steel with a layer of zinc by immersing the metal in a bath of molten zinc at a temperature of around 450 °C to prevent corrosion. During the process, a metallurgically bonded coating is formed which protects the steel from harsh environments. Corrosion prevention is an essential factor in the economic utilization of steel. In suitable applications, no other protective coating matches galvanizing's unique combination of low first cost, ease of inspection for coating quality, durability, predictable performance, low maintenance and resistance to impact and mechanical damage. The most satisfactory way to ensure the safe, effective and economical galvanizing of articles is for the designer, fabricator and galvanizer to work together before the article is manufactured.

Shivam Engineers & Fabricators ensures that the important pre-requisites to galvanizing requires that the design features which aid the access and drainage of cleaning solutions and molten zinc flow into, over, through and out of fabricated articles will improve the quality of the coating.

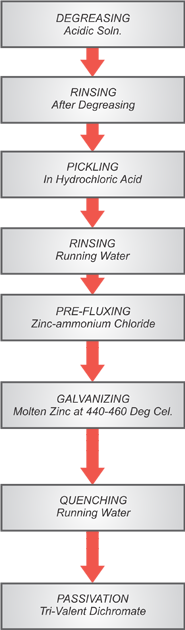

For grease & oil removal from the surface of steel, It is immersed in acid base degreaser.

To clean the surface of carry over salts for effective acid cleaning.

The rust scale & mill scale are removed from the surface of the steel by passing it through 15 to 20% conc. HCL.

Steel is again rinsed to remove acid & iron salts.

Steel is then passed through hot zinc,ammonium chloride to prevent oxidation & ensure that the surface is prime before molten zinc immersion.

Oxide free steel is immersed in molten zinc at a temperature of 450-460 deg Celsius to form zinc–iron alloy. The period of dip depends on the zinc & weight of steel item immersed.

The steel immersed in molten zinc is slowly withdrawn & immersed in cold water to ensure a metallurgically strong bond to steel completely covering the whole steel.

The steel is immersed in Di-chromate solution for providing an envelope film for additional protection to zinc coating during transit or wet storage stains in warehouse.

Please be so kind and send us your enquiry.